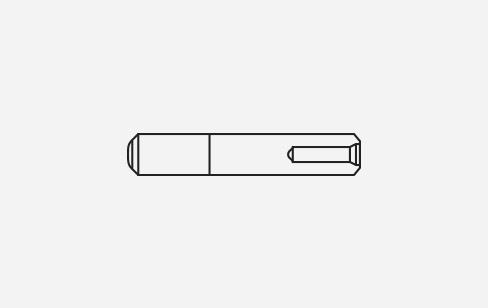

Cylindrical Pins with Internal Thread

Prodotti

- Self-Tapping Screws

- Autofilettanti impronta a croce

- Self-tapping screws with slotted drive

- Varianti autofilettanti

- Autofilettanti testa esagonale

- Autofilettanti di sicurezza con piolino antisvito

- Autofilettanti autoperforanti

- Viti per legno

- Viti rapid per plastica e pannelli truciolari

- Viti di giunzione per mobili

- Viti per fissaggio pannelli cartongesso

- Autofilettanti maschianti solo su richiesta

- Viti per telai a muro

- Viti per serramenti PVC

- Viti metriche

- Viti metriche taglio cacciavite

- Viti metriche impronta croce

- Viti metriche testa esagonale

- Viti metriche cava esagonale

- Viti testa tonda con quadro (TTCQ)

- Viti metriche di sicurezza con piolino antisvito

- Grani

- Viti trilobate

- Barre filettate

- Golfari

- Viti metriche speciali

- Viti con filettatura automaschiante

- Viti registro

- Viti per mobili

- Ingrassatori a sfera

- Dadi

- Rondelle

- Miscellaneous Items

- Ribattini e rivetti

- Inserti filettati

- Tappi filettati conici o cilindrici

- Rivettatrici oleopneumatiche o manuali

- Pins

- Cotter Pins and Snap Pins

- Keys and bits

- Wire springs

- Snap-in Tabs

- Locknuts

- Nylon Components

- Finishing Products

- Elastic Collars

- Cable clamps

- Brass eyelets

- Hose clamps

- Plates or Inserts

- Personalizzazioni

- Trattamenti

- Self-Tapping Screws

- Autofilettanti impronta a croce

- Self-tapping screws with slotted drive

- Varianti autofilettanti

- Autofilettanti testa esagonale

- Autofilettanti di sicurezza con piolino antisvito

- Autofilettanti autoperforanti

- Viti per legno

- Viti rapid per plastica e pannelli truciolari

- Viti di giunzione per mobili

- Viti per fissaggio pannelli cartongesso

- Autofilettanti maschianti solo su richiesta

- Viti per telai a muro

- Viti per serramenti PVC

- Viti metriche

- Viti metriche taglio cacciavite

- Viti metriche impronta croce

- Viti metriche testa esagonale

- Viti metriche cava esagonale

- Viti testa tonda con quadro (TTCQ)

- Viti metriche di sicurezza con piolino antisvito

- Grani

- Viti trilobate

- Barre filettate

- Golfari

- Viti metriche speciali

- Viti con filettatura automaschiante

- Viti registro

- Viti per mobili

- Ingrassatori a sfera

- Dadi

- Rondelle

- Miscellaneous Items

- Ribattini e rivetti

- Inserti filettati

- Tappi filettati conici o cilindrici

- Rivettatrici oleopneumatiche o manuali

- Pins

- Cotter Pins and Snap Pins

- Keys and bits

- Wire springs

- Snap-in Tabs

- Locknuts

- Nylon Components

- Finishing Products

- Elastic Collars

- Cable clamps

- Brass eyelets

- Hose clamps

- Plates or Inserts

- Personalizzazioni

- Trattamenti

Normative

-

ISO 8735

Self-Tapping Screws – Steel C15

| Thread nominal diameter (mm) | Tightening torque Nm |

| 2,2 | 0,450 |

| 2,9 | 1,500 |

| 3,5 | 2,800 |

| 3,9 | 3,400 |

| 4,2 | 4,500 |

| 4,8 | 6,500 |

| 5,5 | 10,000 |

| 6,3 | 14,000 |

| 8 | 31,000 |

Set Screws – Steel 45H

| Thread nominal diameter (mm) | Tightening torque Nm |

| M3 | 0,9 |

| M4 | 2,5 |

| M5 | 5 |

| M6 | 8,5 |

| M8 | 20 |

| M10 | 40 |

| M12 | 65 |

| M16 | 160 |

| M20 | 310 |

| M24 | 520 |

Metric Screws – Steel Grade 8.8, Coarse Thread

| Thread nominal diameter (mm) | Preload N | Tightening torque Nm |

| M3 | 2550 | 1,5 |

| M4 | 3930 | 3,1 |

| M5 | 6360 | 6 |

| M6 | 9000 | 10,4 |

| M8 | 16400 | 24,6 |

| M10 | 26000 | 50,1 |

| M12 | 37800 | 84,8 |

| M14 | 51500 | 135 |

| M16 | 70300 | 205 |

| M18 | 86000 | 283 |

| M20 | 110000 | 400 |

| M22 | 136000 | 532 |

| M24 | 158000 | 691 |

| M27 | 206000 | 1010 |

| M30 | 251000 | 1370 |

Coefficient to be applied to the steel grade values 8.8

| ACC, 4,8 | ACC. 10,9 | ACC, 12,9 |

| 0,500 | 1,406 | 1,688 |

Hex Nuts

| Nominal diameter | Class 8 tightening torque (Nm) | Class 10 tightening torque (Nm) |

| M3 | 4 | 5,2 |

| M4 | 7 | 9,15 |

| M5 | 12,14 | 14,8 |

| M6 | 17,2 | 20,9 |

| M8 | 31,8 | 38,1 |

| M10 | 50,5 | 60,3 |

| M12 | 74,2 | 88,5 |

| M14 | 101,2 | 120,8 |

| M16 | 138,2 | 164,9 |

| M18 | 176,6 | 203,5 |

| M20 | 225,4 | 259,7 |

| M22 | 278,8 | 321,2 |

| M24 | 324,8 | 374,2 |

| M27 | 422,3 | 486,5 |

| M30 | 516,1 | 594,7 |

Practical Method for Adjusting Screwdrivers

Adjust the screwdriver to progressively increasing torque values until the screw breaks. Repeat the test on a certain number of pieces (sample batch) and determine the minimum torque value that causes breakage. Then adjust the screwdriver to a torque equal to 50-60% of this value.